AMR

Pallet Mover User Directed

Easy To Set-Up, Map & Start Missions In Less Than 1 Hour!

Developed in partnership with Thoro.ai, the Big Joe Pallet Mover AMR is an easy to deploy solution for autonomous floor-to-floor pallet transportation and drop-off that companies can set up and put into operation in less than 1 hour. This new Big Joe unit seeks to revolutionize on-demand material handling across a broad number of industries by offering self-driving technology at an accessible price point on one of the most common material handling vehicles, an electric pallet truck. The new Big Joe Pallet Mover works just like a conventional lift truck but features an intuitive user interface, onboard computer, LiDAR, and camera system to transport and drop pallets to locations autonomously once the operator loads it up and selects a mission. This collaborative approach uses self-driving technology as a productivity force multiplier by giving workers the ability to focus on higher-value tasks or direct multiple independent workflows concurrently. With the ability to use the machine in manual mode at any time, the flexibility of the Pallet Mover AMR allows it to bring efficiencies to facilities without intensive changes to their operations or need for any infrastructure other than a wi-fi connection for software updates if desired.- Features

- Specifications

- Videos

The AMR Features:

- 4,400lb Capacity with Autonomous Travel Speed of up to 2.8 MPH

- Intuitive Touch Screen User Interface

- Integrated 205AH UL Recognized Li-ion Battery and 120vac Charger

- Control Head Beacon

- Blue Light

- Stereoscopic Camera

- 270 Degree Forward Facing LiDAR

- Low-profile Forks: 3" to 7.6" Elevation

- Compact Rider Platform

The AMR Specifications:

| • Vehicle Type | User Directed AMR |

| • Capacity | 4,400lbs. @ 24” load center |

| • Power | UL recognized 24v 205AH Li-ion battery |

| • Max Lift Height | 7.6" |

| • Collapsed Height | 2.99" |

| • Fork Dimensions | 27" x 47.25" |

| • Vehicle Dimensions | See specification sheet |

| • Turning Radius | See specification sheet |

| • Travel Speed | See specification sheet |

| • Battery Compartment | See specification sheet |

| • Battery Capacity | See specification sheet |

| • Charger | Onboard 120vac |

The Pallet Mover AMR features an easy to learn user interface accessed via the onboard touchscreen, allowing you to set-up, map and start missions in less than one hour. If you can use a smartphone, you can program the Pallet Mover AMR!

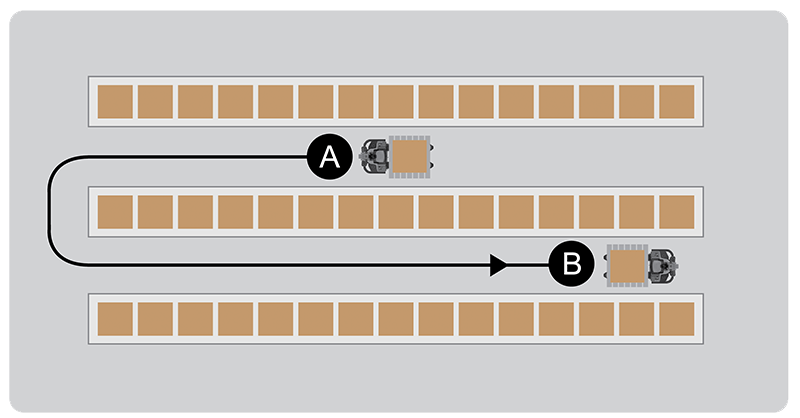

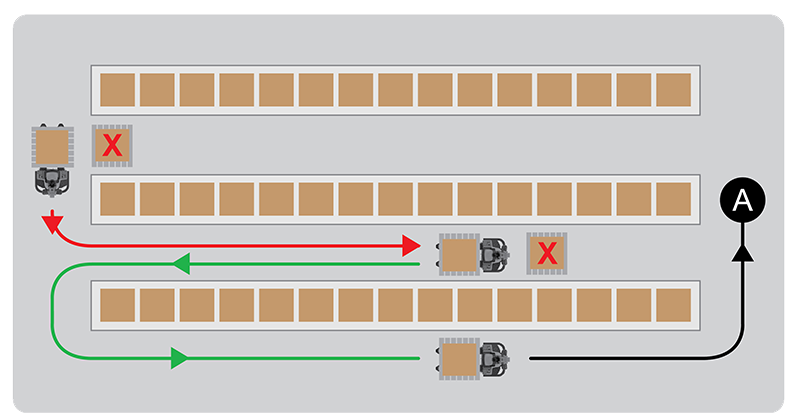

GO TO LOCATION

The Go to Location Function is the most basic operation, essentially shuttling from waypoint to waypoint, with direct operator input at both start and finish. Once at the pre-set location, it will wait for the operator to give it the next task. The Pallet Mover AMR will not drop a pallet in Go to Location mode.

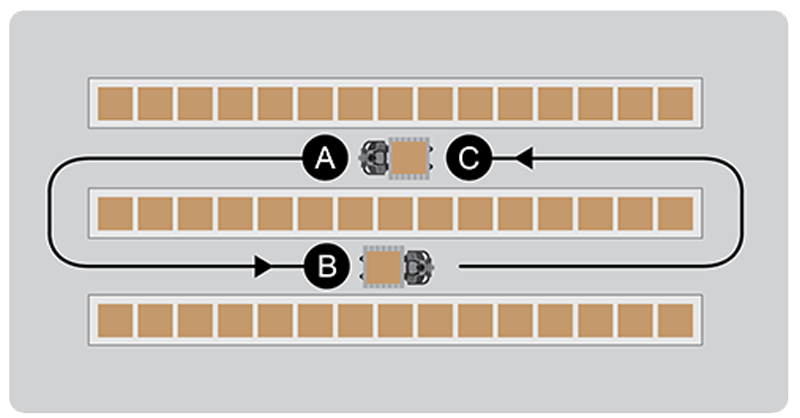

DROP AND RETURN

Drop & Return is the next level of operation, where the unit will navigate to the pre-set waypoint, drop a pallet and return unladen to the start location.

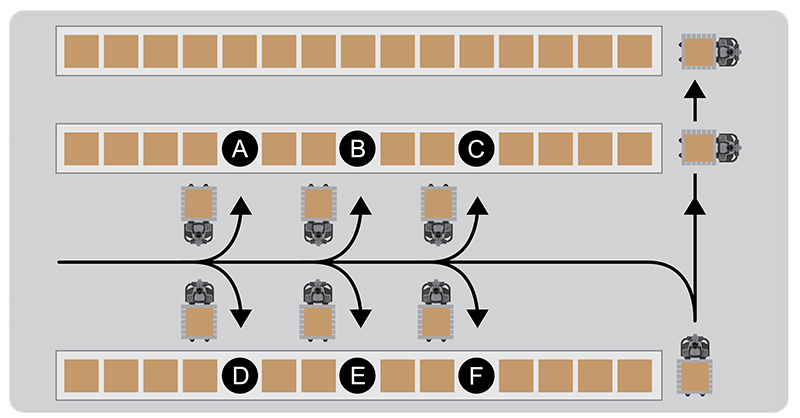

ZONE DROP

Zone Drop is an advanced level of operation where the Pallet Mover AMR will travel to a defined “zone” and drop a pallet in the first location from a pre-set group, based on user priority. It will then return unladen to the start location.

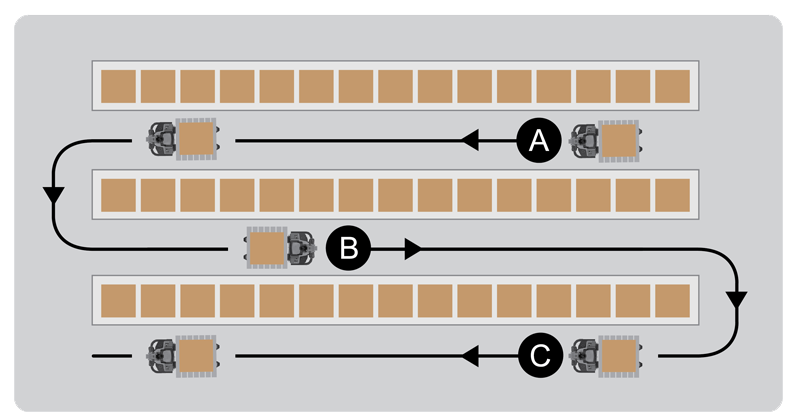

MISSIONS

You can build and save Missions using a series of waypoints, including Drop Zones, and operator interactions. Missions are used to send the Pallet Mover AMR into your facility on a specified route, to a number of waypoints, where it will either wait for an operator interaction, drop a pallet, or proceed to the next waypoint, depending on mission settings.

DYNAMIC MAPPING & ROUTING

You can build and save Missions using a series of waypoints, including Drop Zones, and operator interactions. Missions are used to send the Pallet Mover AMR into your facility on a specified route, to a number of waypoints, where it will either wait for an operator interaction, drop a pallet, or proceed to the next waypoint, depending on mission settings.

ZONE BASED RULES

To further enhance the safe and productive operation of the vehicle when in autonomous mode, zone based rules can be programmed by the user on the onboard user interface. As part of a vehicle mission, such rules can direct the vehicle to honk a horn before entering an aisle, reduce travel speeds in a specific location, or avoid areas as examples of this feature.

THE FORCE MULTIPLIER

The Pallet Mover AMR follows a simple principle which is that technology is best when it helps people get more done and provide more value overall in collaboration with it. Not only does the Pallet Mover AMR reduce the need for manual labor within basic material handling workflows, but by doing so, it allows workers to focus on activities that drive organization profit as opposed to operational cost.

How many more pallets can your workers move with our user directed approach?

What else could they do with the time saved?

SET UP AND GO IN 1 HOUR

The Pallet Mover AMR’s exclusive Thoro.ai self-driving system employs a user-friendly, four-step mapping process that typically takes just one hour to initiate and put into operation.

- Mount an April Tag to a static facility location, which the unit scans to localize, or in other words set its “Zero” position.

- Manually drive the unit around the area that you want it to navigate in.

- Set the waypoints where you want a task performed.

- Create zones and missions to be performed at the waypoints.

DAY 1 ROI

The Pallet Mover AMR is so advanced yet easy to use, it can make an impact on your bottom line immediately upon receipt. You will be able to set up and begin moving product in as little as one hour, eliminating mundane tasks and allow your personnel to focus on higher value or priority tasks.

How much time are workers at your facilities moving materials when they could simply send it and forget it?

Do they have more value added activities they can be doing?

If so, user directed automation will not just provide ROI day one, but everyday from now on to you.

CUSTOM OPTIONS

- External rapid charger

- Universal Carrier load deck for customizable material handling

- Additional fork lengths and widths

VERSATILE TRANSPORT SOLUTION

The Pallet Mover AMR is available with an optional mobile rack. This adjustable, 3-shelf accessory is easily carried by the AMR and provides flexible, organized transport of up to 1,500lbs. of small to mid-sized components, parts, or kits. The 3 shelves are adjustable and feature a raised lip to help parts remain on the rack during transport. The rack is designed to be easily lifted and dropped at workstations, ensuring seamless material presentation and minimizing downtime between transfers.